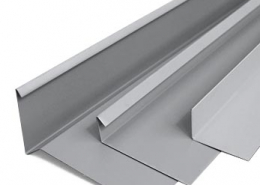

KOMAXIT, Powder Painting

Metal coating with polyester plastic powder paints applied to appropriately pre-treated metal (galvanised, degreased by phosphating) by electrostatic spraying. The coat is cured at a specified temperature for a specified period of time. Different powder types, different curing times and temperatures provide matt or glossy coats including various surface colours and designs.

Advantages of Plastic Powder Surface Finishes Include:

- High-standard surface finish

- Even surface layer (without droplets on the product surface, surface defects, paint irregularities etc.)

- Environment friendliness

- Food-compliant (no harmful chemicals)

- Long life, depending on the purpose of application

Application Range

- Metal fences

- Household appliances

- Railings and building structures

- Street furniture

- Wiring programme

- Automotive parts

- Photo gallery

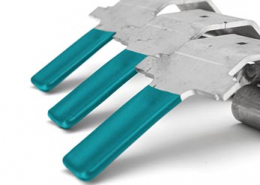

TERMOPLAST, Powder Painting

Thermoplastic coating of metals is based on modified poly-olefins and polyamides and may be applied on soft steel, aluminium and galvanised steel. This coating is designed for electrostatic application.

Basic Characteristics

- Coat thickness range 200-750 micron

- Wide colour range

- Environment friendliness: VOC, TGIC, plasticizer, isocyanate, fire isocyanate, halogen and heavy metal fee

- Full UV resistance: attractive appearance, colour and gloss for decades

- Designed for marine use: long-term salt, sea water, sand and sun resistance

- Hygienic: no mould and fungi growth

- Surface: impact and graffiti resistant

- Easy application: no primer required. Ideal solution of sharp edges and welds

- No cracks and peels

- Very good electric insulation

- Acid resistant

Surface Blasting

Steel granulate abrasive (S) – Steep beads (pellets)

The spherical steel granules of S type are made of specially treated above-eutectoid steel. Their texture is fine, homogeneous, tempered martensitic structure with optimum rebound flexibility and resistance against material fatigue. This material is optimal for most applications requiring blasting with throwing wheels. Properties of this product, especially its long life and impact resistance, provide for cleaning effect maximisation at optimum cost.

Crushed steel abrasive (GH, GL, GP)

Sharp-edged crushed steel is made by crushing of specifically thermally treated granules. This abrasive is used for surface cleaning and treatment. The material is optimal for most applications using compressed air blasting. According to new research results sharp-edged crushed steel is more appropriate and more economical for blasting machines with throwing wheels – these cases require consultation with the commercial department, though. Major advantages of this product include plastic speed and perfection – a better anchoring profile for paint application than in the case of granulate.

Glass bead abrasive

These glass micro beads are ideal for closed blasting systems permitting abrasive recycling. Blasting with glass micro beads is very friendly to the blasted material and can be used for fine polishing of stainless materials.

Maximum product size: 1500 by 2000 by 4000 mm