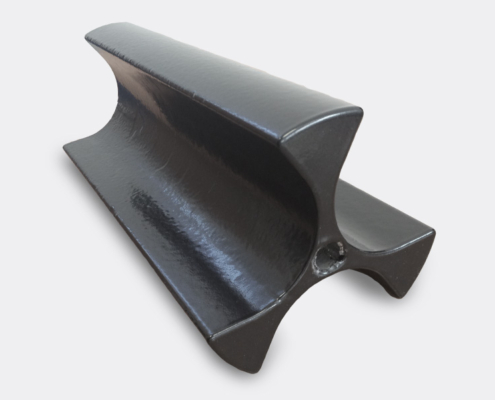

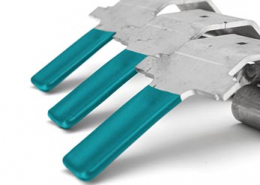

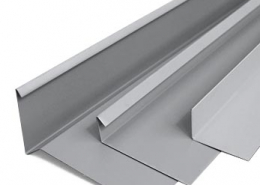

Coating of preheated, degreased metal parts with thermoplastic poly-olefin powder according to customer requirement is designed for engineering, food processing, energy and automotive industries. The thus coated products are resistant to corrosion, chemicals, salts, weather and UV radiation. Coat thickness in the case of this surface finish ranges between 200 – 750 µm, subject to the steel type and thickness.

Weather resistance

Products coated by fluid application of thermoplastic powder are resistant against corrosion, chemicals, salts, airborne pollutants and weather effects. Thermoplastics show excellent adhesion to metals, electrical insulation properties, abrasion and UV resistance.

PVC layer adhesion

- This coat achieves excellent adhesion to metals thanks to its composition.

- Tensile strength (ISO 527-1,-2)** 5 Mpa

- Melting temperature (ISO 3146) 110 – 115 °C

Density

- Subject to colour shade, 0.915 – 0.935 g.cm-3

- Coat hardness

- Shore D (ISO 868) 49

- Thermal stability

- Thermoplastic manufacturer states -40°C to +82°C

UV resistance

Maximum 10 years. Thermoplastic coats are free of heavy metals and volatile substances (VOC-free).therefore they are suitable for food contact.

* Data applicable to 350-micron coat applied under standard conditions and with 3 mm thickness

** This value does not characterise coat adhesion but represents the value at which the applied coat layer peels off